Our Story

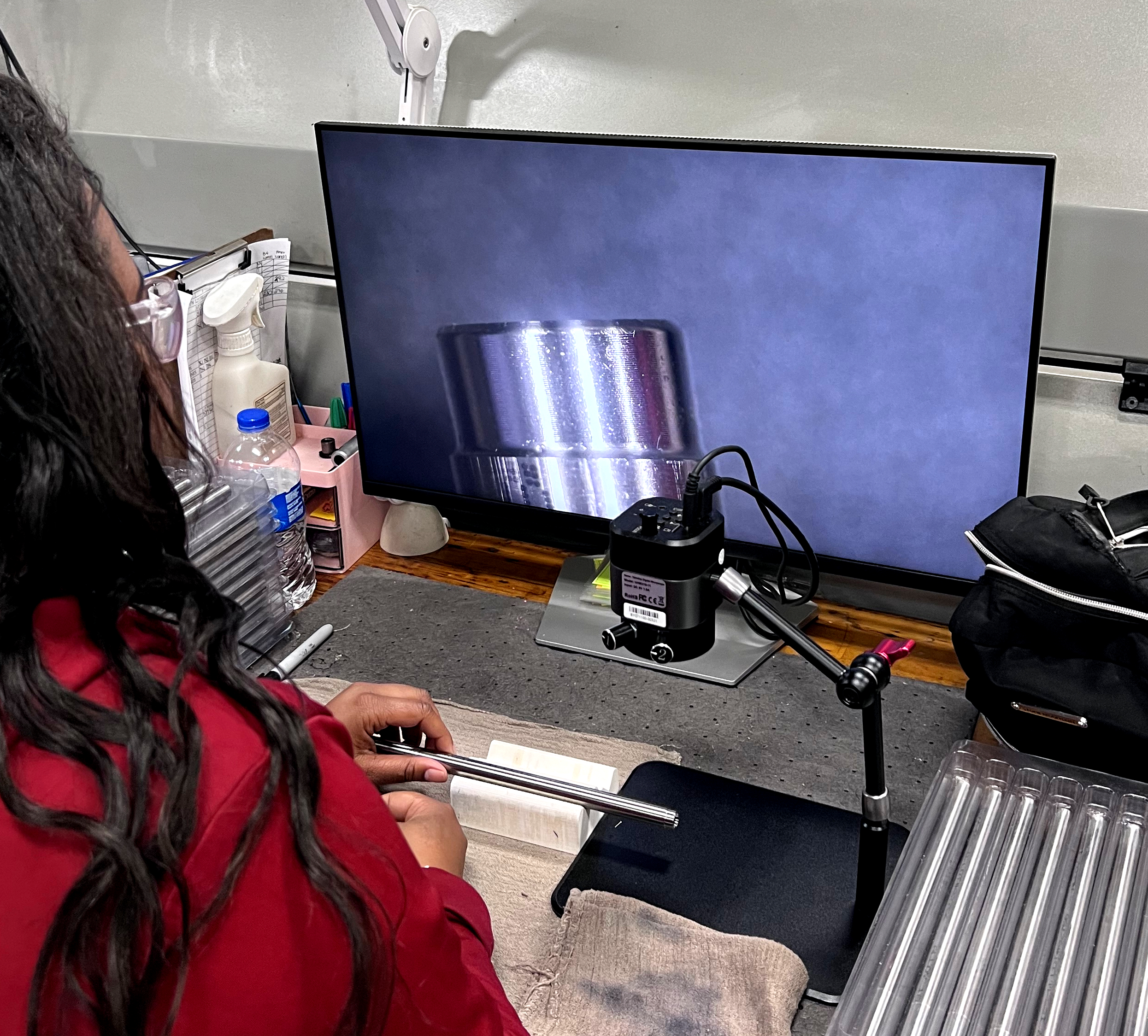

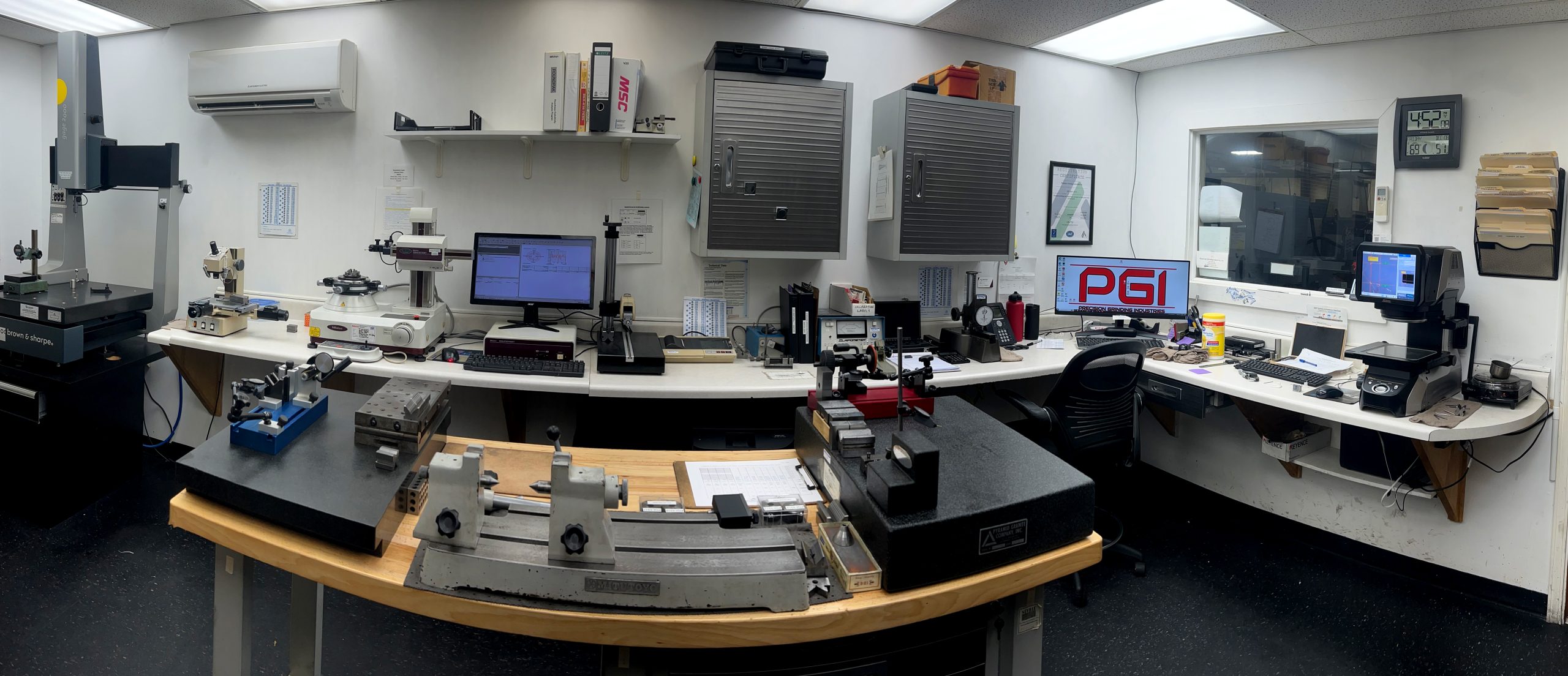

Manufacturing precision components requires precision measurement. PGI has the expansive array of specialized equipment and team of experienced personnel to ensure every job is to print. In addition to first piece, in-process, and final inspections, our sophisticated quality control department can provide formalized data collection, capability assessments, and material certifications. We have been ISO certified for over 2 decades and, most recently, hold an ISO 9001:2015 certificate.

- ISO 9001:2015 Certified

- Fully Climate Controlled Facility

- Mitutoyo Roundtest RA 1500 Cylindrical Measuring Machine with Roundpak Software

- Keyence Vision Measurement System IM-7020

- Mitutoyo SJ-400

- Brown & Sharpe CMM

- Versitron Hardness Testing System

- Wilson Rockwell Superficial Hardness Tester

- OGP Focus Contour Projector

- Additional Equipment

- Carbide Grade 3 Gage Masters

- Tool Makers Microscope

- Micrometers

- Bore Gages

- Electronic and Pneumatic Gaging for OD and ID Measurements

- Dial Indicators

- Thread Gages

- Mantis Visual Inspection Microscopes